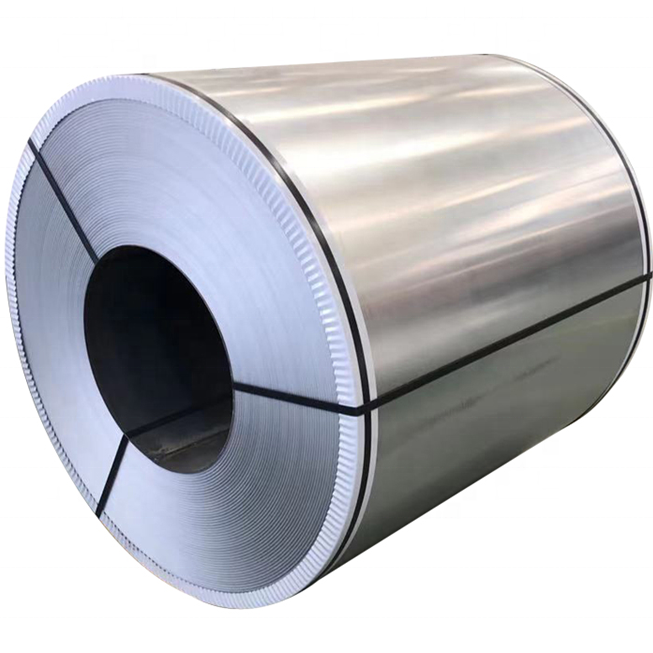

When selecting galvanized steel sheets for residential applications, it’s important to consider multiple factors to ensure the chosen material meets your specific needs while offering durability and quality. Galvanized steel is widely used in industries like construction, furniture, automotive, and electronics. With so many options available on the market, it can be challenging to choose the right type of galvanized sheet. Here’s a guide to help you make an informed decision.

1. Material Type of Galvanized Steel Sheets

Galvanized steel sheets primarily come in two types: hot-dip galvanized and electro-galvanized. Hot-dip galvanized steel sheets are coated with zinc through a dipping process, providing superior corrosion resistance and rust prevention. On the other hand, electro-galvanized steel sheets are coated with zinc using an electroplating method, offering weaker corrosion resistance. When selecting galvanized steel, it’s crucial to understand your specific requirements and choose the material that best suits the intended application.

2. Thickness of Galvanized Steel Sheets

The thickness of galvanized steel sheets plays a significant role in their mechanical performance and lifespan. Generally, thicker sheets provide better strength, corrosion resistance, and longer durability. However, thicker sheets also come at a higher cost. It’s important to balance practicality with cost-effectiveness by selecting the appropriate thickness for your needs. For residential use, choosing the right thickness ensures that the material performs optimally while remaining affordable.

3. Surface Treatment of Galvanized Steel Sheets

The surface treatment of galvanized steel greatly impacts its appearance and performance. Common methods include hot-dip galvanizing, electroplating, and chemical galvanizing. Each method offers different levels of corrosion resistance and aesthetic appeal. For example, hot-dip galvanized sheets are ideal for outdoor applications due to their robust resistance to corrosion, while electro-galvanized sheets are more suitable for decorative purposes in indoor environments.

4. Precision of Galvanized Steel Processing

The processing precision of galvanized steel sheets influences their performance and ease of use. Higher precision in processing leads to better flatness, thickness tolerance, and overall quality. When selecting galvanized sheets, it’s essential to verify that the processing precision meets your requirements to ensure stable and reliable usage.

5. Manufacturer Reputation

Different manufacturers may produce galvanized steel sheets with varying levels of quality, performance, and price. Well-known brands typically follow stricter manufacturing processes and quality control systems, ensuring better product consistency. It’s advisable to choose reputable manufacturers with a proven track record to ensure the quality and cost-effectiveness of the galvanized steel sheets you purchase.

6. Application of Galvanized Steel Sheets

Galvanized steel sheets are used in various applications, each with its own performance requirements. For example, construction galvanized sheets need to have excellent weather resistance and corrosion protection, while furniture galvanized sheets should have a good balance of strength and aesthetics. Automotive galvanized sheets must be durable with high strength and impact resistance. Make sure to select galvanized steel sheets based on the specific demands of your application.

Conclusion

Choosing the right galvanized steel sheets for residential use requires careful consideration of several factors, including material type, thickness, surface treatment, processing precision, manufacturer reputation, and intended application. By understanding these elements, you can select the most suitable galvanized steel that meets your needs and offers long-lasting performance. Additionally, proper care and maintenance will ensure that the galvanized steel sheets retain their quality over time.