Aluminum panels are commonly used as facade materials, but if the quality is not up to standard, it can be dangerous for users and compromise the safety of building projects. For the entire aluminum panel industry, selling low-quality products at low prices erodes customer confidence in aluminum panels. Therefore, it is essential to reject low-quality aluminum panels.

In the aluminum panel industry, quality not only affects the decorative effect but also the practical use of the panels. So, what are the key factors affecting the quality of aluminum panels? Below, we’ll discuss some of the main points.

1. Cutting Corners

With the continuous improvement of the national quality control system, the phenomenon of cutting corners has become less rampant, but some companies still take risks to reduce production costs. They cut corners by using substandard molds in the production of aluminum panels, which leads to issues like insufficient thickness of the aluminum panel’s supporting parts.

2. Mixed Raw Materials

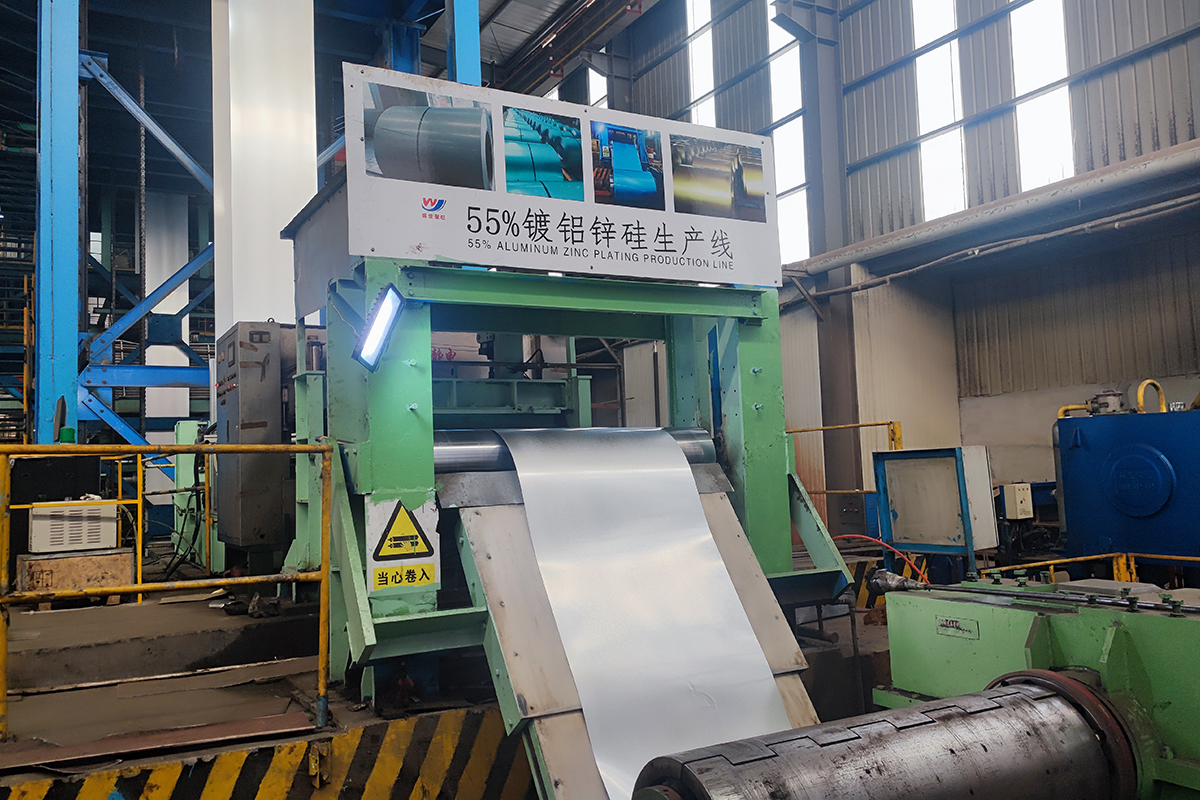

The aluminum panel industry still lacks a comprehensive and mature industry standard, resulting in raw material quality varying greatly. Some companies, in a bid to compete with low prices, use mixed aluminum or add recycled aluminum in their production processes, which lowers production costs but compromises the material quality.

3. Inadequate Supervision

Some companies fail to establish proper supervision systems, creating loopholes in raw material monitoring. This results in the inclusion of substandard raw materials with improper chemical elements, leading to the production of aluminum panels with excessive chemical elements, which can severely impact quality.

4. Untimely Testing

During the aluminum panel coating process, a solution virus needs to be prepared. If the preparation process doesn’t follow regulations or the solution concentration is not tested in a timely manner, the aluminum oxide film will become too thin and fail to meet the required standard thickness.

5. Deceptive Practices

The basis for settlement of aluminum panel products is based on the area between the dealer and the customer, and weight between the dealer and the manufacturer. Because the settlement standards differ, some manufacturers take advantage of the situation and manipulate wall thicknesses to their advantage.