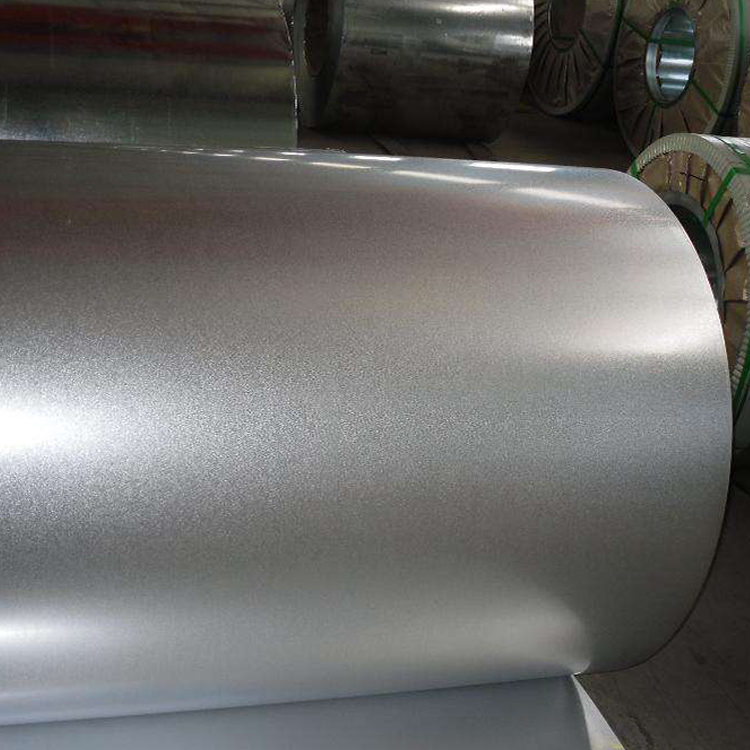

Galvanized steel sheets, a common metal material, are widely used in various civil sectors due to their excellent corrosion resistance. This remarkable property is one of the primary reasons for their widespread application across industries such as construction, home appliances, and automotive manufacturing.

Key Characteristics of Galvanized Steel Sheets

Galvanized steel sheets are created by coating a steel substrate with a layer of zinc through processes like hot-dip galvanizing or electroplating. This zinc layer serves not only as a physical barrier, preventing corrosive agents from directly contacting the steel base but also provides cathodic protection via electrochemical action, further enhancing the steel’s durability and longevity. The combination of these features significantly improves the material’s resistance to environmental degradation.

Corrosion Resistance of Galvanized Steel Sheets in Civil Applications

- Construction Industry

In the construction sector, galvanized steel sheets are commonly used for roofing, wall panels, and other structural components. These components are often exposed to the elements, including rain, wind, and intense sunlight, all of which can cause corrosion. The corrosion resistance of galvanized steel sheets allows them to withstand these environmental factors, helping to maintain the integrity and safety of the building structures over time.

- Home Appliance Industry

Galvanized steel sheets are widely used in the manufacture of appliances like refrigerators and washing machines. These household items often come into contact with water, oils, and other corrosive substances during their use. The corrosion-resistant properties of galvanized steel ensure that the appliances’ exteriors remain free from rust and degradation, thereby extending their lifespan and enhancing their durability.

- Automotive Industry

In the automotive industry, galvanized steel sheets are utilized in the production of car bodies, chassis, and other vital components. These parts are frequently exposed to corrosive elements such as rainwater, mud, and road salts. Galvanized steel’s excellent corrosion resistance helps to protect these automotive parts from rust and degradation, ensuring the safety, performance, and reliability of vehicles on the road.

Factors Affecting the Corrosion Resistance of Galvanized Steel Sheets

While galvanized steel sheets offer significant corrosion resistance, their performance can be influenced by several factors. The thickness and quality of the zinc layer, the composition and quality of the steel substrate, and the environment in which the steel is used all play vital roles in determining its corrosion resistance. For example, harsh environments with high humidity or exposure to aggressive chemicals can accelerate the rate of corrosion.

To enhance the corrosion resistance of galvanized steel, manufacturers typically focus on optimizing production processes, improving the quality and thickness of the zinc layer, and selecting high-quality steel substrates. Additionally, proper care and maintenance during use are crucial to ensuring the material’s longevity and effectiveness in resisting corrosion.

Conclusion

Galvanized steel sheets demonstrate exceptional corrosion resistance, making them a versatile and durable material for use in the construction, home appliance, and automotive industries. By understanding the factors that influence their performance and taking appropriate measures to enhance their corrosion resistance, both manufacturers and users can maximize the lifespan and reliability of galvanized steel applications.