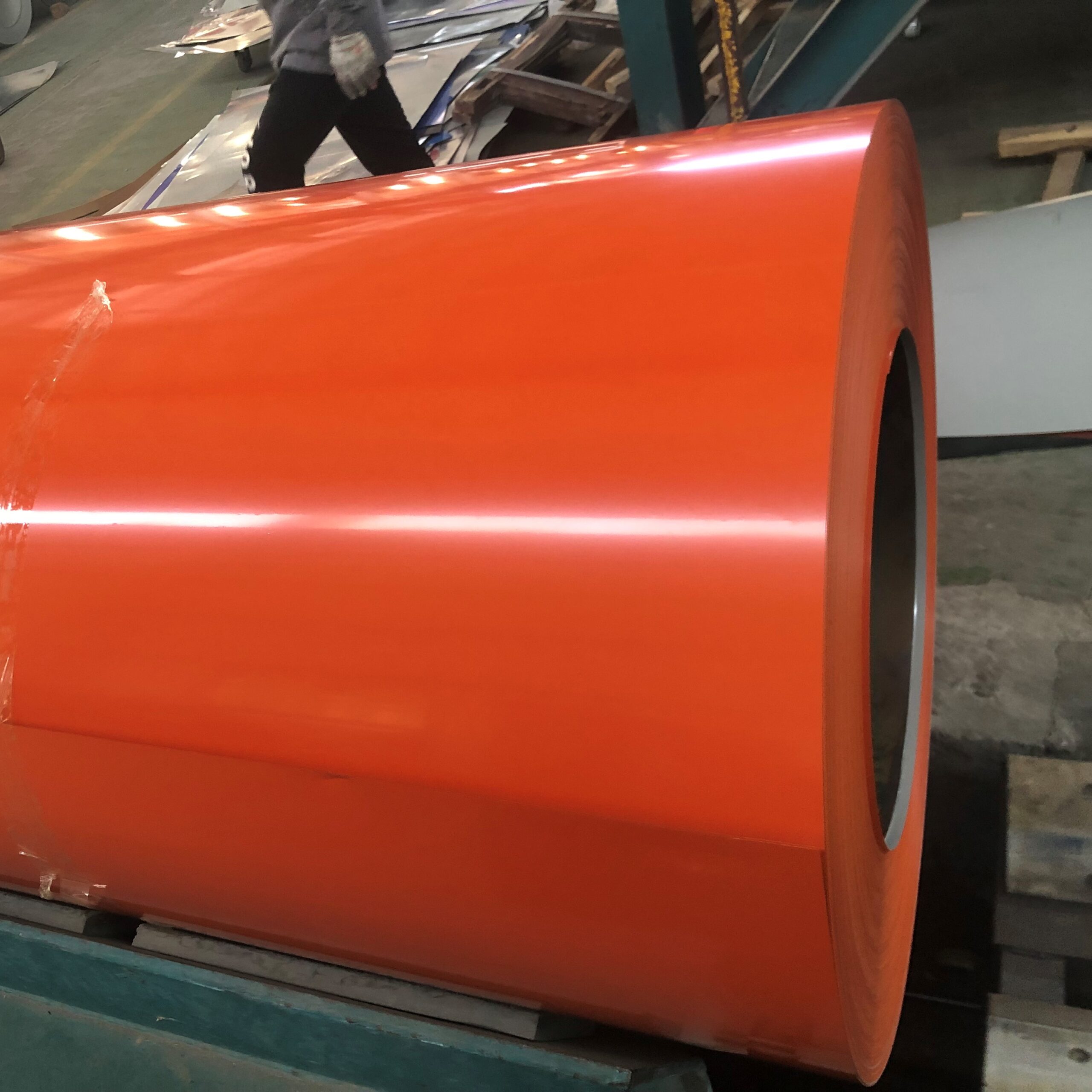

Coated steel sheets, also known as color-coated steel sheets or color steel sheets, are produced by applying a coating to a base material of cold-rolled steel or galvanized steel. The process involves surface pre-treatment (degreasing, cleaning, chemical conversion), followed by continuous application of a coating (roller coating), and then baking and cooling the product. The resulting coated steel sheets are lightweight, visually appealing, and highly resistant to corrosion. These materials provide a new raw material for industries such as construction, shipbuilding, vehicle manufacturing, household appliances, and electrical industries. They have the added benefits of substituting wood, promoting energy-saving, and reducing pollution.

Production Process:

The commonly used two-coat, two-bake continuous color-coating process includes the following steps:

- Unwinding machine → Stitching machine → Pressing roller → Tension machine → Unwinding active tension → Alkaline washing and degreasing → Cleaning → Drying → Passivation → Drying → Initial coating → Initial baking → Finish coating → Finish baking → Air cooling → Rewinding active tension → Rewinding machine → (Final winding and packaging)

Applications:

Color-coated steel sheets made from galvanized steel not only benefit from the protective zinc layer but also the organic coating, which acts as a protective barrier, preventing rust. These products typically have a longer lifespan than galvanized steel, with a 50% increase in longevity. However, the lifespan of these coated sheets can vary significantly depending on the region and the specific application areas. For instance, areas with high sulfur dioxide levels or salt content, like industrial or coastal regions, experience faster corrosion. Additionally, in places with significant temperature fluctuations or high humidity, corrosion may occur more quickly, reducing the lifespan. Buildings or factories made from coated steel sheets benefit from the durability of the material, especially when frequently washed by rainwater. Therefore, designing roofs with a greater slope reduces dust accumulation, improving durability. For areas not regularly washed by rain, periodic cleaning with water is recommended.

Applications by industry:

- Household appliances: 31%

- Construction: 63%

- Others: 6%

Coated steel sheets have a broad range of applications, including in the construction, home appliance, transportation, packaging, machining, interior decoration, medical, and automotive industries.

Quality Features:

- Cost-effectiveness: The production process of coated steel sheets has a minimal environmental impact and is recyclable, significantly reducing pollution. Additionally, their light weight reduces the material needed for structural support, lowering construction costs.

- Ease of processing and construction: Coated steel sheets can be rolled into various shapes and lengths, with no overlapping seams in the middle. They are easy to construct, provide excellent waterproofing, and offer good aesthetic results.