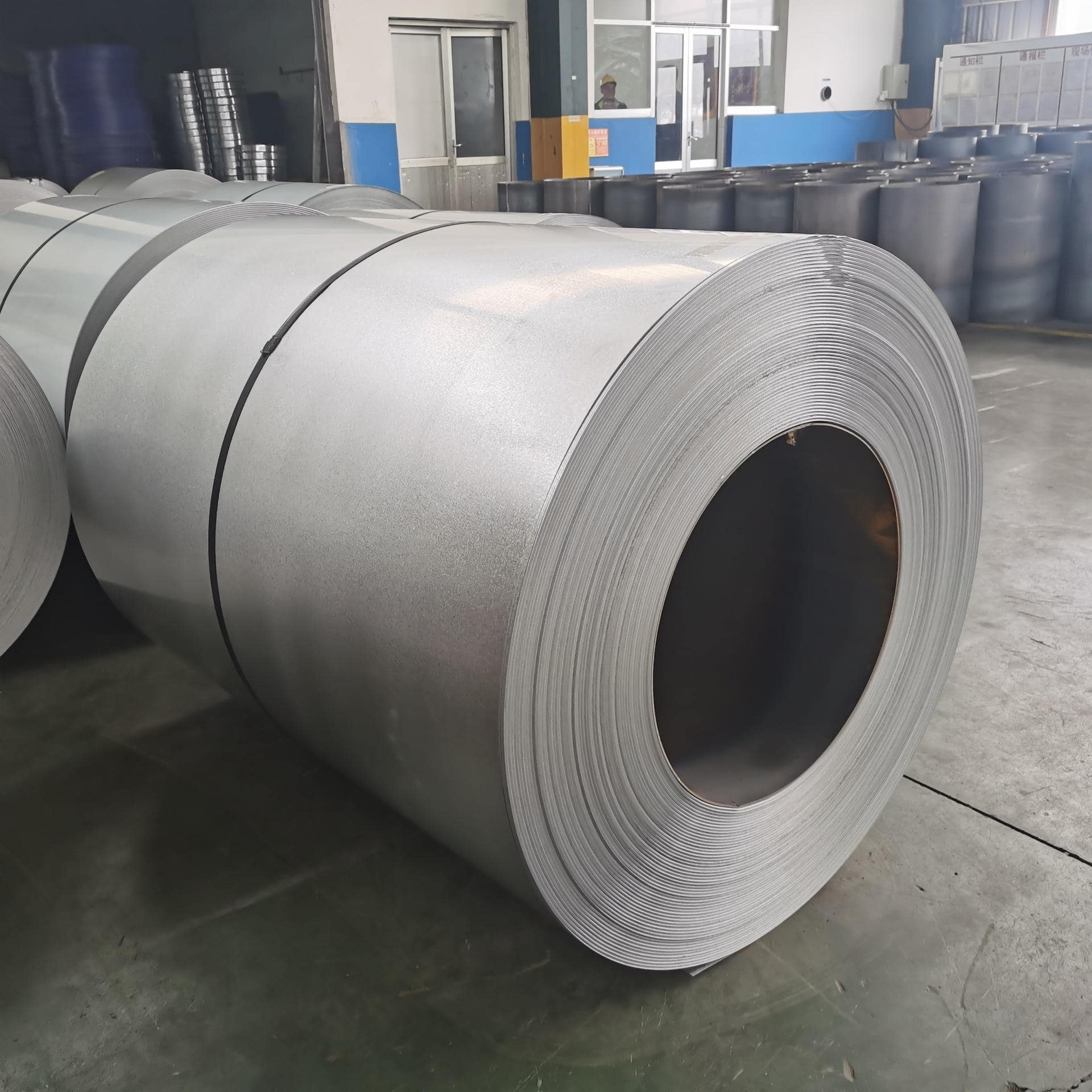

Aluminum zinc-coated steel sheets, a modern steel material, are increasingly replacing galvanized steel due to their superior corrosion resistance. These sheets are made from cold-rolled steel that undergoes hot-dip galvanization. With the growing use of aluminum zinc-coated steel in various industries worldwide, it is crucial to understand its exceptional features that make it stand out as an innovative and durable material.

1. Excellent Corrosion Resistance

One of the most notable features of aluminum zinc-coated steel sheets is their exceptional corrosion resistance. The material’s corrosion resistance is 6-8 times greater than that of ordinary galvanized steel, with a lifespan of up to 20 years without rust. The corrosion protection is primarily due to the formation of a dense aluminum oxide layer when the aluminum corrodes, effectively preventing further damage to the underlying steel.

2. High Temperature Oxidation Resistance

Aluminum zinc-coated steel sheets offer excellent resistance to high-temperature oxidation. At temperatures of up to 315°C, these sheets do not discolor or deform. The aluminum-zinc alloy composition ensures that the steel can withstand temperatures above 300°C without significant changes, making it similar in performance to aluminum-coated steel sheets.

3. High Thermal Reflectivity

Another key benefit of aluminum zinc-coated steel is its high thermal reflectivity, which exceeds 75%. This is twice as high as that of galvanized steel, making it an ideal material for energy-efficient applications, as it helps in reflecting heat and maintaining optimal temperature conditions.

4. Good Processability

Aluminum zinc-coated steel is highly processable, allowing for easy stamping, cutting, and bending. This versatility in fabrication ensures that the material can be tailored to meet the needs of various construction and manufacturing projects.

5. Aesthetic Appearance

With its attractive silver-white finish and snowflake-like patterns, aluminum zinc-coated steel sheets are visually appealing. The aesthetic quality of the surface makes it suitable for applications where appearance matters, such as in architecture and design. Additionally, these sheets can be used directly without the need for additional paint or coatings.

6. Superior Surface Coating

Aluminum zinc-coated steel provides a superior base for further coatings, such as paint. Its composite coating, combining aluminum and organic materials, offers enhanced protection, preventing corrosion even beneath the organic layers, ensuring long-lasting performance.

7. Widespread Usage

Aluminum zinc-coated steel sheets have a wide range of applications, from construction to manufacturing. Their ability to resist corrosion in various environments has led to their extensive use across different sectors worldwide.

8. Cost-Effectiveness

These sheets are cost-effective as they cover a larger surface area than galvanized steel, offering 3% more surface area. This results in savings in terms of material usage and provides a higher return on investment for construction and industrial projects.

9. Long Lifespan and Durability

The durability of aluminum zinc-coated steel sheets is unmatched, with their outdoor lifespan reaching 8-15 years. Their high resistance to environmental factors such as rust, abrasion, and weather conditions ensures that they maintain their appearance and function over time.

10. Environmental Benefits

Aluminum zinc-coated steel sheets are environmentally friendly due to their reduced need for post-processing and maintenance. With fewer steps involved in production and less requirement for galvanizing, these sheets contribute to a greener, more sustainable construction industry.