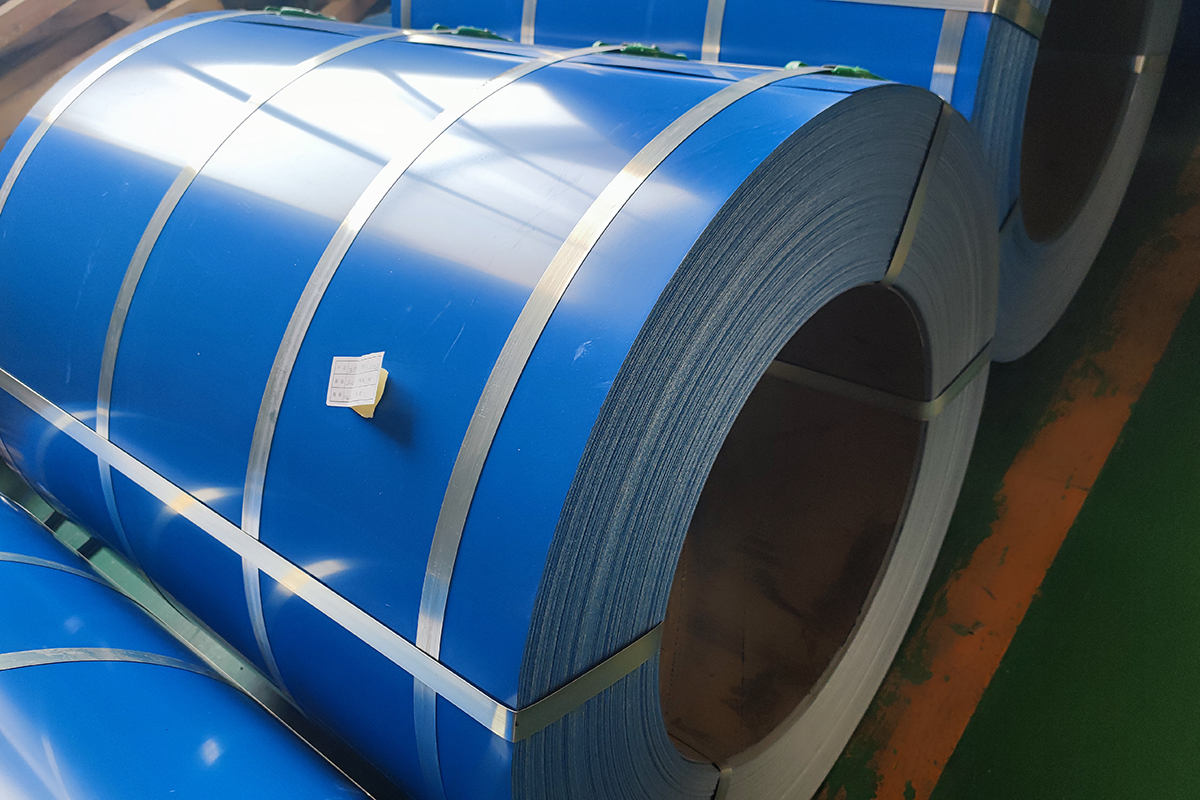

Color coated steel sheets are produced on continuous lines using cold-rolled steel and galvanized steel as the substrates. These substrates undergo surface pre-treatment, followed by roller coating with one or more layers of liquid coating, and are then baked and cooled to produce the final sheet. So, what are the different types of substrates used for color coated steel sheets? Let’s take a closer look.

1. Cold-Rolled Substrate Color Coated Steel Sheets

Color coated sheets made from cold-rolled substrates offer a smooth and aesthetically pleasing appearance, with the same processing properties as cold-rolled steel. However, any minor scratches on the surface coating can expose the cold-rolled base material to air, leading to rust formation on the exposed iron. Therefore, these products are typically used for temporary isolation measures or indoor applications where durability is less critical.

2. Hot-Dip Galvanized Color Coated Steel Sheets

Hot-dip galvanized color coated steel sheets are made by applying an organic coating to a hot-dip galvanized steel sheet. The organic coating not only provides the protective properties of zinc but also offers heat insulation and rust resistance, significantly extending the product’s service life compared to bare galvanized sheets. The zinc coating on hot-dip galvanized substrates typically ranges from 180g/m² (on both sides), with high zinc content for outdoor substrates up to 275g/m².

3. Hot-Dip Aluminum-Zinc Color Coated Steel Sheets

Hot-dip aluminum-zinc color coated steel sheets are produced by applying an organic coating to hot-dip galvanized steel sheets. These steel sheets contain a composition of 55% aluminum and 5% zinc in the alloy, offering enhanced corrosion resistance and durability.

4. Electro-Galvanized Color Coated Steel Sheets

Electro-galvanized color coated steel sheets are produced by applying an organic coating to electro-galvanized steel sheets and then baking the coating. Electro-galvanized sheets typically have a thinner zinc layer, usually around 20/20g/m², making them unsuitable for outdoor applications like exterior walls and roofs. However, due to their appealing appearance and excellent processing properties, they are commonly used in the manufacturing of household appliances, audio equipment, steel furniture, and indoor decorations.

Applications of Color Coated Steel Sheets

These color-coated sheets are suitable for cutting, bending, rolling, stamping, dust-proofing, and film lamination. Metal steel sheets are often used as surface materials in modern decorative designs due to their mildew resistance. The sheets are highly resistant to acid and alkali, and the base metal offers good corrosion resistance, providing excellent chemical resistance.

In addition, fire-resistant PVC high-temperature composite boards utilize a unique fire-resistant PVC film material, classified as flame-retardant with a fire rating of B1. The material has self-extinguishing properties to prevent prolonged burning, and the strong adhesion between the film and steel ensures long-term durability, making it easy to maintain at a low cost.

The weather resistance of color-coated sheets can be further enhanced by adding UV-resistant formulations, ensuring they retain their color for years. These products are also environmentally friendly. PVC-coated steel sheets are easy to clean, scratch-resistant, and help reduce maintenance and labor costs, making them a practical and eco-friendly choice for various applications.