Aluminum zinc coated steel is known for its remarkable performance in various environments. Here are the nine key characteristics that make it a top choice for many industries:

1. Superior Corrosion Resistance

Aluminum zinc coated steel offers exceptional corrosion resistance, being 6-8 times more resistant than regular galvanized steel. The corrosion protection is primarily due to the aluminum layer. When the zinc layer wears off, the aluminum forms a stable oxide layer that prevents further corrosion, ensuring the steel remains rust-free for up to 20 years under various environmental conditions.

2. High-Temperature Oxidation Resistance

This material is highly resistant to high-temperature oxidation. It can withstand temperatures of up to 315°C without discoloration or deformation. The alloy’s excellent heat resistance, similar to galvanized steel, makes it ideal for use in high-temperature environments.

3. High Thermal Reflectivity

Aluminum zinc coated steel has an outstanding thermal reflectivity of over 75%, which is twice that of galvanized steel. This high reflectivity helps improve energy efficiency in applications requiring temperature control.

4. Good Workability

This material is highly versatile and can be easily processed to meet various manufacturing requirements. It can be punched, sheared, and bent, making it suitable for many industrial applications.

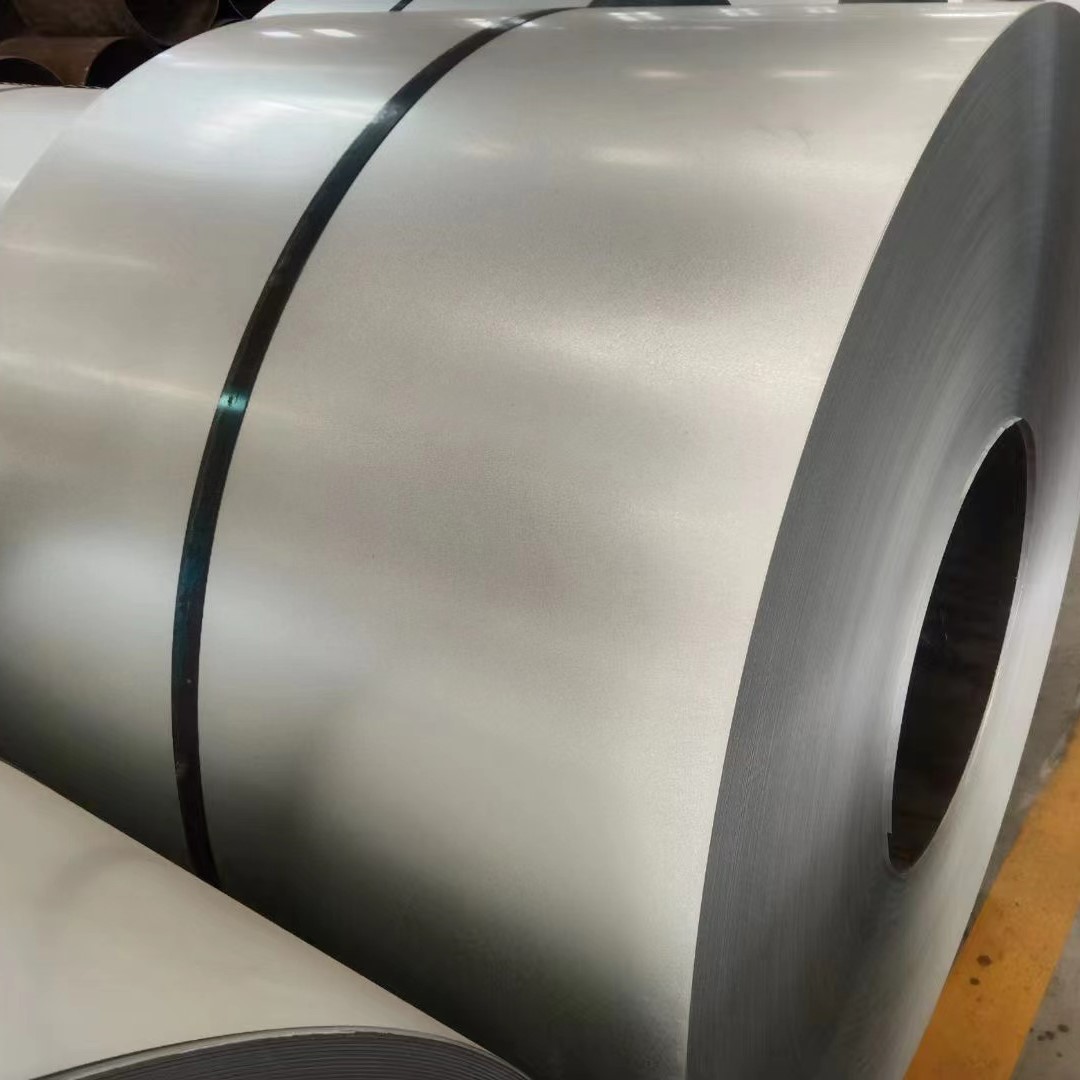

5. Aesthetic Appearance

Aluminum zinc coated steel has an attractive silver-white finish with a snowflake pattern. Its aesthetic appeal means it can be used without additional coating or painting, making it both a practical and visually appealing material.

6. Suitable for Surface Coating

It serves as an excellent substrate for surface coatings. The aluminum zinc coating provides a strong base for organic or composite coatings, enhancing the material’s corrosion protection and ensuring durability even under challenging conditions.

7. Greater Effective Coverage

Aluminum zinc coated steel offers more effective surface area compared to galvanized steel when the zinc coating thickness is the same. This means that for the same weight of material, aluminum zinc coated steel provides more usable surface area, improving its overall efficiency.

8. Surface Treatment Options

Various surface treatments are available for aluminum zinc coated steel, including passivation, oil coating, and phosphating. These treatments further improve the material’s corrosion resistance and durability under moist storage and transportation conditions. Custom treatments can also be provided based on customer requirements.

9. Cost-Effective

Aluminum zinc coated steel is more cost-effective than galvanized steel. Due to its lower density (55% aluminum and 43% zinc), the same thickness of aluminum zinc steel covers more area, making it more economical. Additionally, the use of oil or other coatings can enhance its corrosion resistance, reducing maintenance costs over time.