Galvanized Color-Coated Steel Coil Industry: Surviving Global Turmoil and Shaping the Future Landscape

I. Geopolitical Games Restructure Global Supply Chains

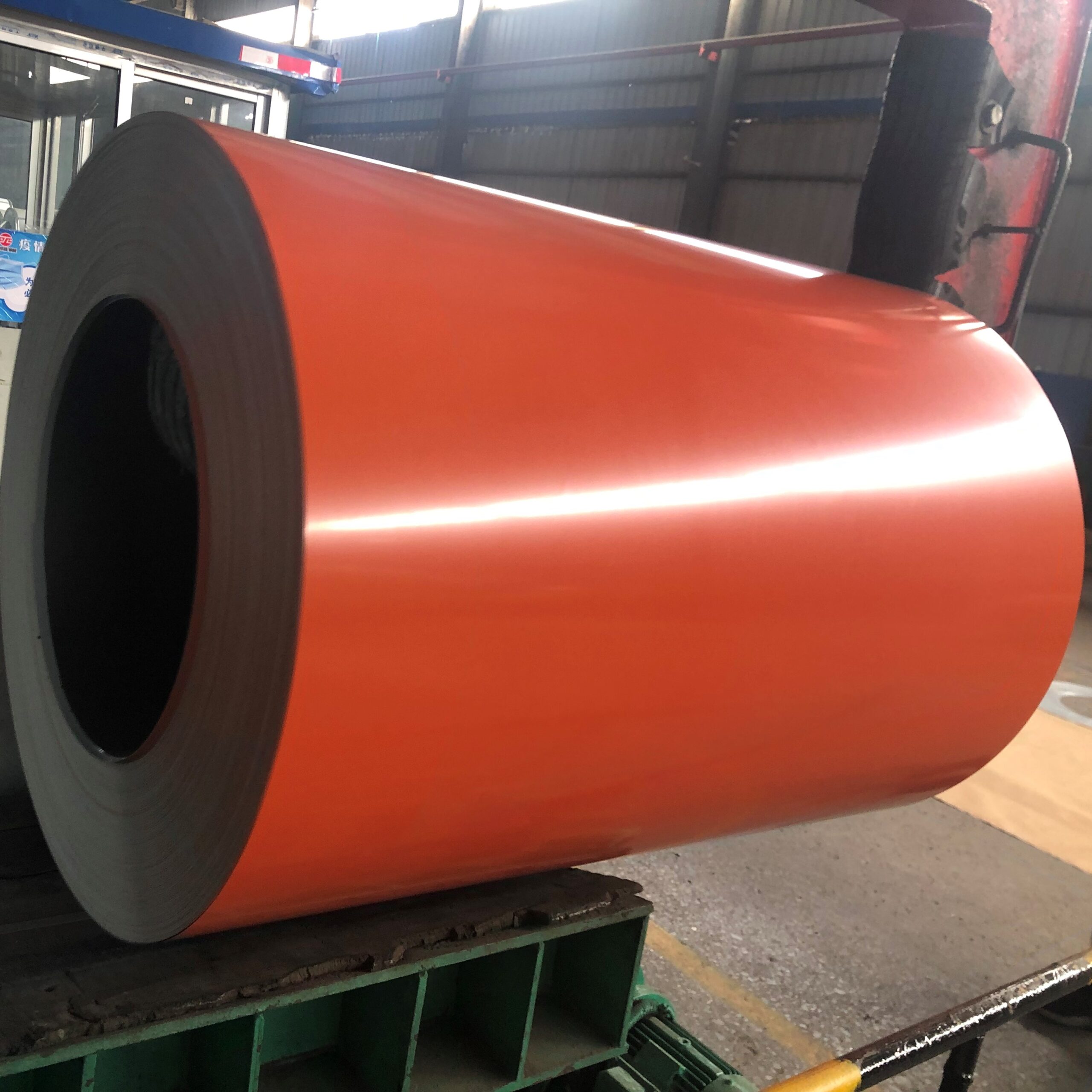

The galvanized color-coated steel coil industry is undergoing profound supply chain restructuring amid the escalating Sino-US trade friction. Since March 2025, the US has imposed a 25% tariff on Mexican imports containing Chinese steel products, directly impacting China’s transshipment channel to North America via Mexico. Data shows that Mexico, as the third-largest source of US steel imports, re-exported 3.2 million tons of steel from China in 2024, with galvanized color-coated coils accounting for over 40%. This policy has forced Chinese enterprises like Langzoholding to accelerate production base in Southeast Asia, where galvanized production capacity in Vietnam and Indonesia grew by 27% year-on-year in 2024, becoming core regions for industrial transfer.

Langzoholding has been at the forefront of this shift, establishing state-of-the-art production facilities in Vietnam’s Binh Duong Province, strategically positioned to serve both regional and global markets while mitigating tariff risks.

Langzoholding has been at the forefront of this shift, establishing state-of-the-art production facilities in Vietnam’s Binh Duong Province, strategically positioned to serve both regional and global markets while mitigating tariff risks.

II. Regional Market Diversification and Emerging Opportunities

Infrastructure booms in Africa and the Middle East are opening new growth frontiers. Mega-projects like Nigeria’s Lagos Light Rail and Saudi Arabia’s NEOM future city have surged demand for galvanized color-coated coils, driving an 18% year-on-year increase in African galvanized pipe exports in 2024 and South Africa’s hot-dip galvanized steel pipe production exceeding 200,000 tons. Langzoholding has secured major contracts for these projects, leveraging its local logistics networks to ensure timely delivery and competitive pricing.

Meanwhile, Southeast Asia exhibits “dual-track development”: Vietnam leverages cost advantages for low-to-medium-end production, exporting 1.2 million tons of galvanized coils in 2024; while South Korea’s POSCO invests in high-end coating lines in Malaysia, targeting high-value sectors like automotive panels. Langzoholding balances both segments, operating a mid-to-high-end production line in Thailand that supplies premium products to automotive manufacturers in the ASEAN region.

Meanwhile, Southeast Asia exhibits “dual-track development”: Vietnam leverages cost advantages for low-to-medium-end production, exporting 1.2 million tons of galvanized coils in 2024; while South Korea’s POSCO invests in high-end coating lines in Malaysia, targeting high-value sectors like automotive panels. Langzoholding balances both segments, operating a mid-to-high-end production line in Thailand that supplies premium products to automotive manufacturers in the ASEAN region.

III. Technological Revolution and Industrial Upgrading Paths

III. Technological Revolution and Industrial Upgrading Paths

Digital transformation is reshaping industry competition. Langzoholding’s smart factory in Jiangsu, equipped with 5G+industrial internet solutions, has achieved a 20% boost in production efficiency and a 15% reduction in energy consumption. Its automated inventory management system cuts inventory turnover days from 45 to 18, setting a benchmark for lean manufacturing in the sector. The breakthrough of 3D digital printing metal (DPM) technology is even more disruptive: Langzoholding’s R&D team collaborated with German engineering firms to adapt this technology for mass production, enabling customizable 3D-textured metal surfaces with 90% lower energy consumption than traditional methods.

Material innovation creates both substitution risks and upgrading opportunities. While aluminum-magnesium alloys gain ground in automotive lightweighting, Langzoholding has doubled down on high. Its proprietary zinc-nickel alloy coating extends color-coated panel lifespan to 25 years—50% longer than conventional products—winning certification from major international standards bodies and securing partnerships with global construction giants.

IV. Key Trends for the Next Decade

- Green Manufacturing as an Entry Barrier: The EU plans to expand CBAM to all steel downstream products by 2030, pushing the industry toward hydrogen steelmaking and CCUS technologies. Langzoholding is advancing a pilot hydrogen-based smelting project in Shandong, aiming to reduce carbon emissions per ton of steel by 50% by 2028, aligning with global decarbonization goals.

- Accelerated Formation of Regional Supply Chains: Free trade agreements like USMCA and RCEP will strengthen “nearshore manufacturing,” with intra-Asia galvanized trade expected to rise from 42% to 55% by 2030. Langzoholding has already established a regional distribution hub in Singapore, optimizing cross-border logistics to serve customers in RCEP member states more efficiently.

- Digital Twin Reconstructing Industrial Ecology: Emulating success stories like Siemens’ MindSphere platform at HBIS, Langzoholding is implementing a digital twin system across its global production network, predicting equipment failures with 90% accuracy and reducing downtime by 35%. This technology-driven approach is set to become a core competitive edge in the industry.

In this era of intertwined globalization and localization, Langzoholding exemplifies how enterprises can navigate complexity by integrating geopolitical foresight, technological innovation, and regional . As the industry evolves, companies that prioritize adaptive strategies—like Langzoholding’s dual focus on green tech and digital transformation—will not only survive but thrive in the decade ahead.

In this era of intertwined globalization and localization, Langzoholding exemplifies how enterprises can navigate complexity by integrating geopolitical foresight, technological innovation, and regional . As the industry evolves, companies that prioritize adaptive strategies—like Langzoholding’s dual focus on green tech and digital transformation—will not only survive but thrive in the decade ahead.