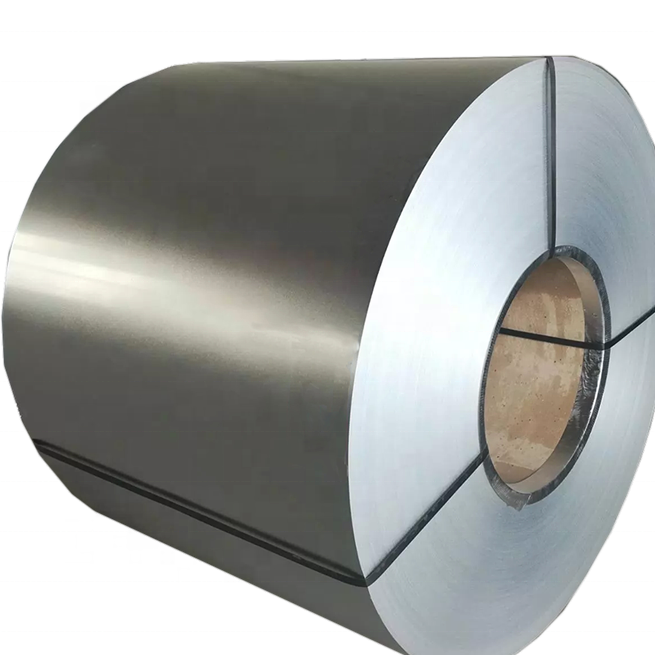

Aluzinc steel sheets, known for their anti-corrosion, weather resistance, and aesthetic appeal, are widely used in the construction industry. These sheets are produced by coating a substrate with an aluminum-zinc alloy layer, which provides exceptional durability and outdoor performance. Below are some common classifications of aluzinc steel sheets based on coating type, substrate material, and surface treatment.

1. By Coating Type

- Hot-Dip Aluzinc Sheets:

These sheets are manufactured by applying an aluminum-zinc alloy coating through a hot-dip process. The uniform coating provides excellent weather resistance and anti-corrosion properties, making them suitable for outdoor construction materials. - Electro-Galvanized Aluzinc Sheets:

These are produced through an electrolytic deposition process, creating a smooth and uniform coating. Known for their superior surface finish and decorative qualities, they are ideal for indoor applications. - Color-Coated Aluzinc Sheets:

These sheets undergo an additional color-coating process over the aluminum-zinc layer. The diverse colors and textures offer enhanced decorative effects, making them perfect for building facades and roofing.

2. By Substrate Material

- Steel Substrate:

Aluzinc steel sheets with a steel base combine the strength of steel with the corrosion resistance of the aluminum-zinc coating. They are widely used for external walls, roofs, and indoor decorations. - Aluminum Substrate:

These sheets feature an aluminum base, providing excellent corrosion and weather resistance with reduced weight. They are suitable for similar applications, including walls, roofs, and interiors.

3. By Surface Treatment

- Galvanized Surface:

This treatment involves directly applying the aluminum-zinc alloy layer to the substrate, forming a consistent protective coating. It enhances corrosion resistance and is suitable for outdoor environments. - Color-Coated Surface:

Following galvanization, a layer of color coating is applied. The varied color and texture options enable decorative applications, especially for facades and roofs.

Conclusion

The versatility of aluzinc steel sheets makes them a popular choice for construction needs. Selecting the appropriate type based on coating, substrate, and surface treatment ensures enhanced durability and aesthetic appeal for specific applications. Understanding these classifications allows for informed decisions, optimizing both functionality and longevity in construction projects.