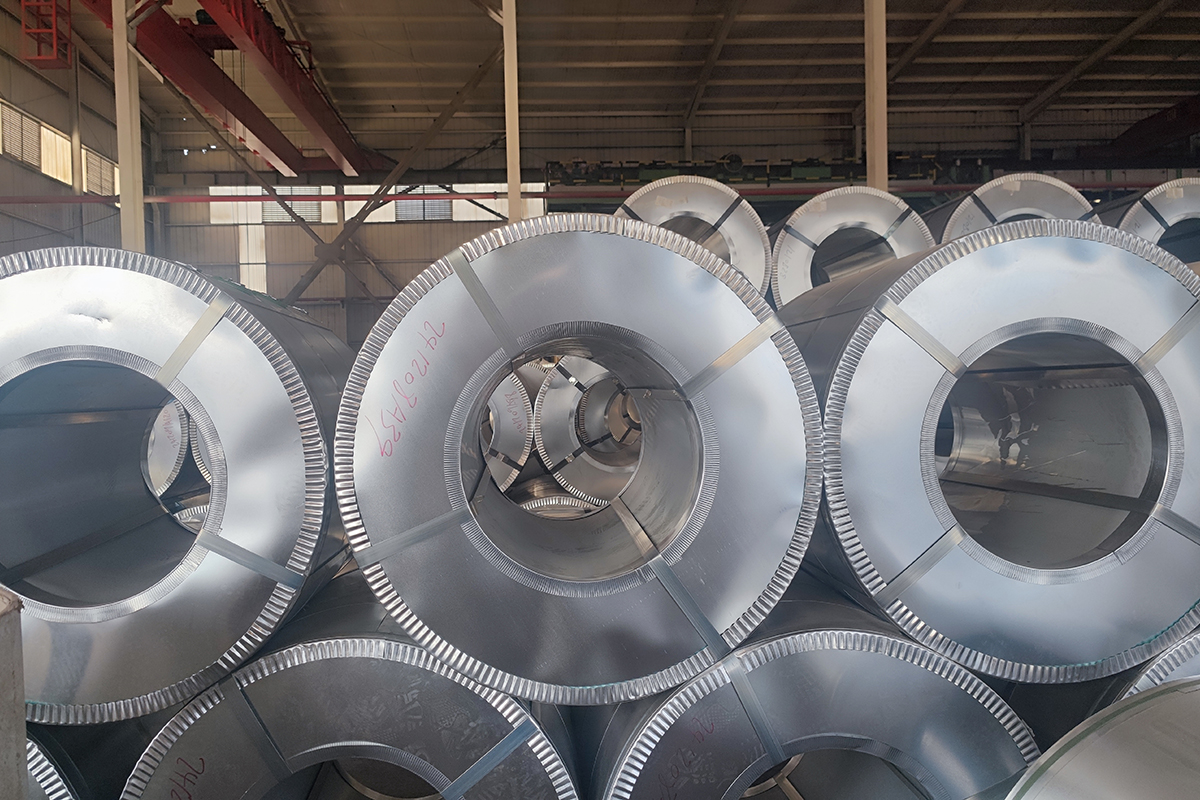

Aluminum-zinc coated steel, also known as Al-Zn steel, has become a widely used material in various industries such as construction, automotive, and furniture manufacturing. This steel is known for its excellent corrosion resistance, durability, and aesthetic appeal, making it a preferred choice for many applications.

Applications of Aluminum-Zinc Coated Steel

Aluminum-zinc coated steel is commonly used in building materials due to its strong physical properties. It is often used in the construction of outdoor buildings, factory structures, warehouses, and other architectural applications. The material’s exceptional resistance to corrosion, high impact resistance, and thermal performance make it ideal for roofing, waterproofing, insulation, and enhancing the structural integrity of high-rise buildings. In addition, aluminum-zinc coated steel is increasingly utilized in the automotive industry for manufacturing durable parts and components that require high strength and resistance to harsh environmental conditions.

In the furniture industry, aluminum-zinc coated steel is often used for products that need to withstand outdoor conditions. Its aesthetic appearance and easy maintenance make it popular for various design applications. The material is also commonly used in electronic industries for components requiring heat resistance and stability.

Key Features of Aluminum-Zinc Coated Steel

- Corrosion Resistance

One of the main advantages of aluminum-zinc coated steel is its superior corrosion resistance compared to traditional galvanized steel. The zinc-aluminum alloy coating provides a protective layer that shields the steel substrate from environmental damage. This is particularly beneficial in areas with high humidity, rain, or other corrosive environmental conditions. - Impact and Shock Resistance

Aluminum-zinc coated steel exhibits excellent impact resistance, which makes it suitable for high-stress applications, such as roofing and structural components exposed to external forces like wind or vibrations. This property ensures the material’s long-lasting durability even under harsh physical conditions. - Thermal Performance

The material has outstanding thermal properties, including heat resistance and insulation capabilities. This makes aluminum-zinc coated steel an excellent choice for buildings requiring temperature control, such as warehouses or factory facilities where thermal management is essential. - Flexibility and Versatility

Aluminum-zinc coated steel is available in a wide range of thicknesses, from 1mm to 4mm, to meet specific customer requirements. The flexibility in thickness allows manufacturers to adjust the material for different load-bearing applications. It can also be customized with various surface finishes, including glossy, matte, single-color, or multicolored coatings, which enhances its aesthetic appeal. - Longevity and Low Maintenance

The aluminum-zinc coating ensures that the material is resistant to wear, corrosion, and environmental damage. Its surface is easy to clean and maintain, making it ideal for outdoor applications that require minimal upkeep. The material maintains its visual appeal and functionality over time, ensuring a long service life with reduced maintenance costs. - Environmentally Friendly

Aluminum-zinc coated steel is highly regarded for its environmentally friendly properties. It is recyclable, contributing to sustainability efforts in the construction and manufacturing industries.

Conclusion

Aluminum-zinc coated steel is an excellent choice for various industries due to its impressive combination of durability, corrosion resistance, and aesthetic versatility. It has become an essential material in construction, automotive, and furniture manufacturing, providing both functional and visual benefits. Its long-lasting performance and ease of maintenance make it a preferred material for a wide range of applications, ensuring its continued popularity in the market.