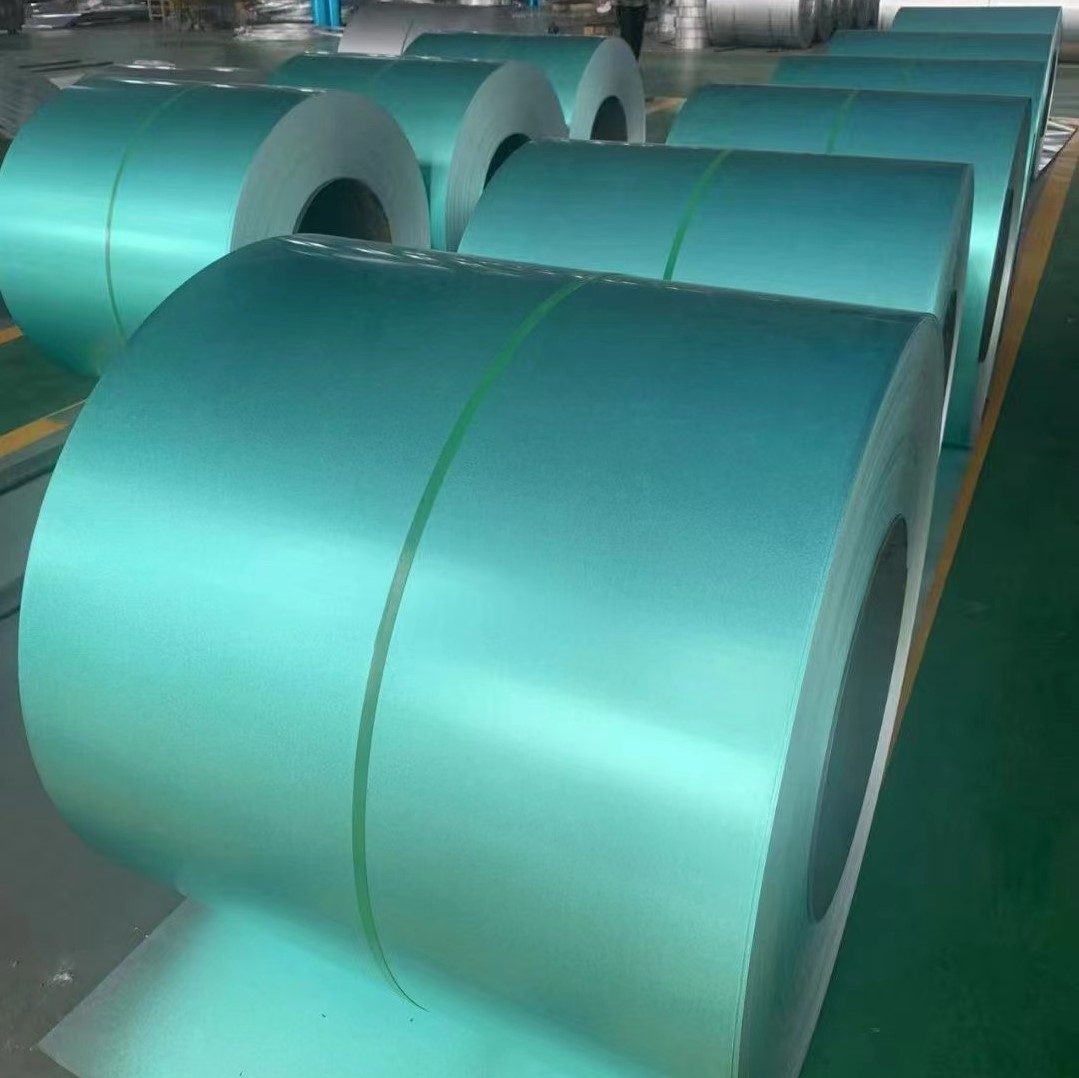

Purification panels, made from materials like color-coated steel and stainless steel, are widely used in industries that require stringent environmental control, such as electronics, pharmaceuticals, and cleanroom spaces. These panels offer several advantages that make them indispensable in maintaining clean, safe, and functional spaces. Below are the key advantages of purification panels:

Self-cleaning and Anti-pollution Properties

Purification panels have self-cleaning surfaces, which require minimal maintenance. Dust and dirt can be easily washed off with water, and the panels exhibit excellent hydrophobic and oil-repellent properties. These panels are designed to remain clean without accumulating stains, ensuring a hygienic environment.

Cleanliness and Bacterial Resistance

The surface of purification panels is coated with silver ions, which prevent the growth of various infectious bacteria. This feature significantly reduces the spread of diseases, making purification panels ideal for environments such as hospitals, clinics, and laboratories where cleanliness is paramount.

Anti-static and Radiation Protection

Purification panels feature special conductive coatings that are designed for clean and medical spaces. The coating offers excellent electromagnetic shielding, ensuring that medical equipment functions properly and providing protection for both staff and patients from harmful static electricity and radiation exposure.

Additional Advantages of Purification Panels

Acid and Alkali Resistance

Purification panels are resistant to acids and alkalis, making them suitable for environments where chemicals are frequently used. This resistance prevents corrosion, protecting the walls and minimizing the need for additional maintenance, which is especially beneficial in hospitals and laboratories that require stringent sanitation measures.

Long Lifespan

The outer layer of purification panels is coated with a wear-resistant resin that provides excellent durability. Over time, the panels maintain their gloss and do not easily experience color fading or wear, ensuring that they look new and continue to perform well even after years of use.

Durability and Maintenance-Free

Thanks to their robust construction and high resistance to wear, purification panels are designed for long-term use. Once installed, these panels require minimal maintenance and will remain effective in maintaining a clean environment without frequent updates or replacements.

Purification Panel Applications and Classification

As the demand for cleanroom construction grows, the use of purification panels is expanding across various industries. The range of applications is vast, and the performance of the panels continues to improve to meet diverse needs. However, it is essential to understand the classification of purification panels to select the right type for specific environments.

Purification panels are commonly classified into types based on their core materials, such as rock wool, glass wool, glass magnesium, aluminum honeycomb, and paper honeycomb. Each type of panel is suitable for different environments, ensuring the appropriate balance of insulation, fire resistance, and cleanliness:

- Rock Wool Panels – Known for excellent fire resistance, these panels are widely used in laboratory and temperature-sensitive environments.

- Glass Wool Panels – With a smooth surface and high fire resistance, these panels are used in demanding environments like cleanrooms and surgical areas, offering durability and resistance to chemicals, wear, and contamination.