PPGL Coils Industry: In – depth Analysis from the Perspective of Tariff Policies

I. Tariff – induced Shifts in Global Trade Landscape

The global PPGL coils industry has been significantly buffeted by a series of tariff adjustments in recent years. The United States, a major consumer in the global steel market, has frequently resorted to tariff hikes as a tool in its trade policy arsenal. In the wake of concerns over the large volume of imported steel products allegedly disrupting the domestic market, the US Department of Commerce initiated comprehensive investigations. As a result, anti – dumping and countervailing duties were imposed on imported PPGL coils.

For certain Asian exporters, especially those from China, these tariffs have been particularly steep, soaring as high as 50% in some cases. This was mainly due to the perception that Chinese steel products were being sold at unfairly low prices, which, according to US authorities, threatened the viability of domestic steel producers. Such high tariffs have had a profound impact on the price competitiveness of imported products in the US market. For instance, a standard 1 – tonne batch of high – quality PPGL coils that previously entered the US market at a competitive price of around $800 now, with the 50% tariff, has to be priced at $1200, making it far less appealing to American buyers.

This situation has forced industry players like Langzoholding to take drastic actions. Langzoholding, which once heavily relied on the US market for a substantial portion of its PPGL coils exports, witnessed a sharp decline in its US – bound shipments. In response, the company’s management, known for their proactive decision – making, quickly assembled a task force. This task force, composed of market analysts, trade experts, and business strategists, conducted in – depth research. Leveraging their in – depth market research capabilities, they identified emerging economies in South America and Africa as potential growth areas.

Langzoholding immediately initiated negotiations with local distributors and partners in these regions. In South America, they targeted countries like Brazil and Argentina, where there was a burgeoning demand for construction materials due to large – scale infrastructure projects. In Africa, they focused on Nigeria and South Africa, which were experiencing rapid urbanization. By tailoring their product range to meet the specific needs of these regions, such as developing PPGL coils with different corrosion – resistance levels suitable for the humid climates of some African countries, Langzoholding aims to establish a strong foothold and offset the losses incurred from the US market. This shift in export destinations also reflects a broader trend among global steel exporters, as they seek to reduce their over – reliance on the volatile US market and diversify their risks.

II. EU’s Regulatory Tariffs and Quality – driven Adaptations

II. EU’s Regulatory Tariffs and Quality – driven Adaptations

The European Union’s approach to tariffs in the PPGL coils industry is more intertwined with its product standard regulations. Concerned about environmental impact and product safety, the EU Commission introduced new, stringent requirements regarding the chemical content in coatings. These regulations stipulate strict limits on harmful substances such as lead, cadmium, and certain volatile organic compounds (VOCs) in the coatings used on PPGL coils. Non – compliance with these standards results in high import tariffs, which can range from 20% to 40% depending on the degree of deviation from the set norms.

This regulatory – tariff combination is designed to ensure that only environmentally friendly and high – quality products enter the EU market. For forward – looking companies like Langzoholding, meeting these EU standards has become a complex and costly but necessary endeavor. A significant chunk of Langzoholding’s annual R&D budget has been earmarked for developing eco – friendly coating formulas. Their in – house team of top – notch chemists and materials scientists worked around the clock.

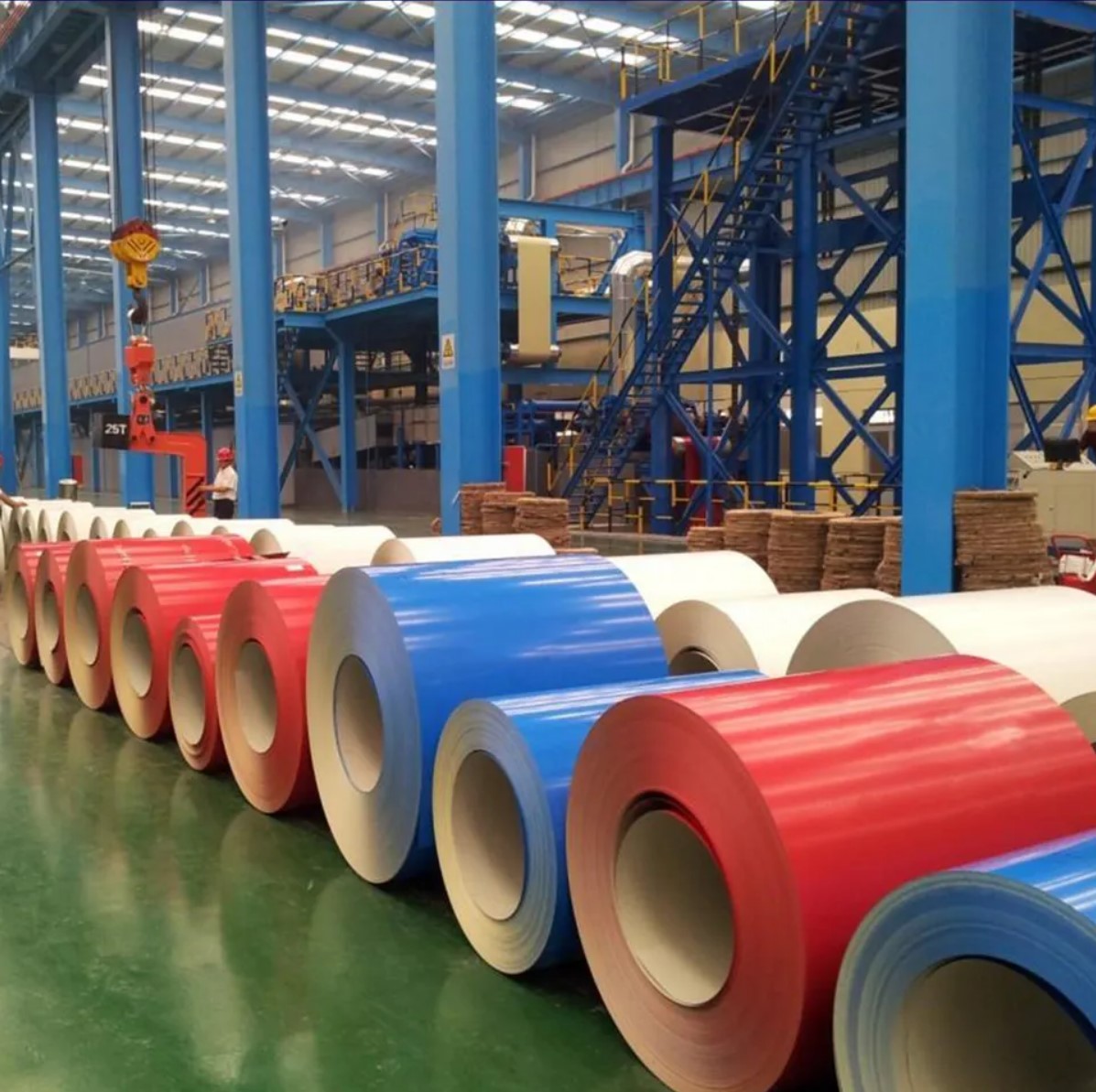

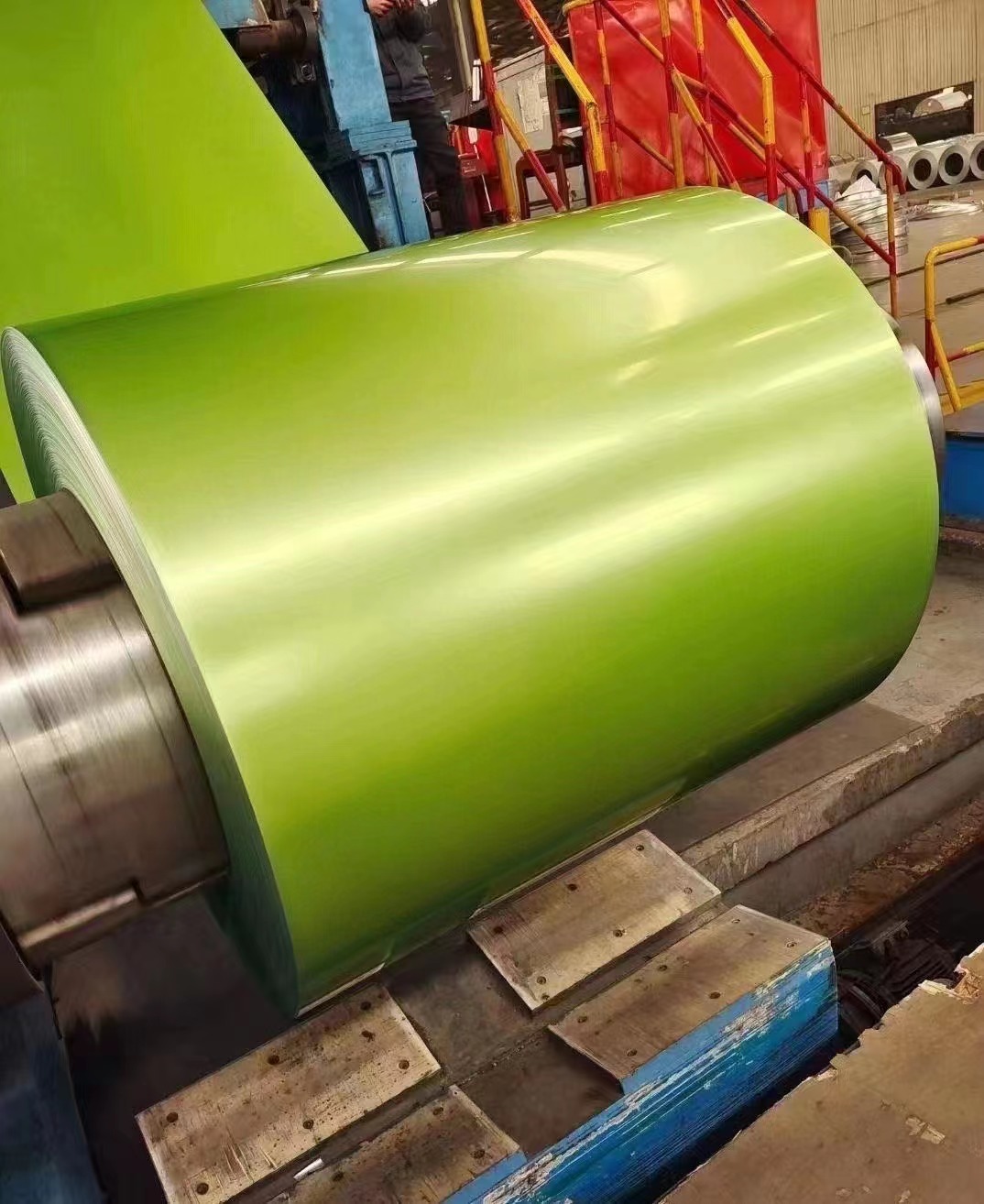

They conducted countless experiments, testing different combinations of raw materials and manufacturing processes. After months of research, they developed new formulas that not only passed the strict EU chemical content tests but also maintained the product’s performance and aesthetic qualities. For example, the new coatings offer enhanced color fastness, ensuring that the color of the PPGL coils does not fade easily even after years of exposure to harsh weather conditions. By investing in such R&D, Langzoholding can continue to access the EU market, which is known for its high – value demand and large consumer base.

However, this also means that the cost of production for EU – bound products has increased. The new eco – friendly raw materials are often more expensive, and the manufacturing process requires more precision and quality control. To mitigate this, Langzoholding is exploring ways to streamline its production processes. They have adopted state – of – the – art lean manufacturing principles, eliminating waste in production steps such as coil handling and coating application. They are also using advanced analytics to source raw materials more cost – effectively while maintaining the high – quality standards demanded by the EU. By analyzing market trends and supplier data, they have been able to negotiate better prices with some of their long – term suppliers without sacrificing the quality of the materials.

III. Asian Tariff Dynamics and Intra – regional Market Realignments

III. Asian Tariff Dynamics and Intra – regional Market Realignments

In Asia, countries such as Vietnam and South Korea have also implemented tariff measures that impact the PPGL coils industry. Vietnam, aiming to protect its domestic steel industry which has been grappling with issues such as high production costs and insufficient domestic capacity, imposed anti – dumping tariffs on imported galvanized steel products, including PPGL coils, from countries like China. These tariffs were determined through a detailed investigation process by the Vietnamese Ministry of Industry and Trade. The tariffs range from 4.43% to as high as 37.13% in some cases, depending on factors such as the degree of price undercutting and the volume of imports.

For Langzoholding, the Vietnamese market, which was previously a significant export destination, has become more challenging to penetrate. However, Langzoholding views this as an opportunity to engage in value – added trade. Instead of simply exporting finished PPGL coils, Langzoholding is considering setting up local manufacturing or assembly facilities in Vietnam. By doing so, the company can not only avoid the high import tariffs but also contribute to the local economy and supply chain.

Langzoholding plans to transfer some of its advanced manufacturing technologies to the local facility. This includes implementing its energy – efficient coating application technology, which reduces the consumption of both energy and coating materials. By creating high – quality jobs and demonstrating their commitment to the local market, they hope to win over local customers and regulatory authorities.

South Korea, on the other hand, has targeted specific steel products like thick steel plates used in the shipbuilding industry with import tariffs. Although this may not directly target PPGL coils, it does disrupt the overall steel supply chain in the region. Since the steel industry is highly interconnected, changes in the availability and cost of one type of steel product can have a ripple effect on others. For example, if the price of thick steel plates increases due to tariffs, shipbuilders may reduce their orders for other steel – related products, which could indirectly impact the demand for PPGL coils used in ship interiors or on – board facilities.

Langzoholding closely monitors these developments in South Korea and adjusts its production and trading strategies accordingly. They are exploring alternative markets for products that may be affected by the South Korean tariff policies, such as focusing more on the domestic market in China or targeting other Southeast Asian countries with growing construction and manufacturing sectors. They are also actively collaborating with South Korean companies to find mutually beneficial solutions, such as joint research projects on new steel alloys that could potentially reduce the overall cost and improve the performance of steel products across the board, thereby alleviating the impact of tariffs.

IV. Future Trajectories Amidst Tariff Uncertainties

IV. Future Trajectories Amidst Tariff Uncertainties

Looking ahead, the future of the PPGL coils industry in the context of tariffs remains uncertain. However, several trends are emerging. As more countries implement protectionist tariff policies, companies like Langzoholding will need to continue diversifying their markets and product portfolios. Investing in R&D to develop products that meet different countries’ regulatory and tariff – related requirements will be crucial. For example, developing products with even more sustainable and compliant coatings will not only help in navigating the EU’s tariff – standard maze but may also open doors to other environmentally conscious markets.

Moreover, there will be an increasing trend towards regionalization of the steel industry. Companies may opt to set up production facilities closer to their target markets to avoid high import tariffs. This could lead to the development of more integrated regional supply chains in Asia, Africa, and South America. Langzoholding is likely to expand its overseas production capacity through joint ventures or wholly – owned subsidiaries in key emerging markets. By doing so, the company can better adapt to local tariff regulations, reduce transportation costs, and respond more quickly to local market demands. In conclusion, while tariffs pose significant challenges, they also present opportunities for innovation and strategic realignment in the PPGL coils industry, and Langzoholding is well – positioned to take advantage of these opportunities.